-

- Week9 Overview

- Introduction and Project Task Distribution

- Work Process

- Part Inspection and Basic Assembly

- Purchasing Guide Wheels

- Part Layout and Checklist Verification

- Using Chaihuo Maker Space Parts

- Part Fitting and Adjustment

- Flexibility Testing and Troubleshooting

- Belt Purchase and Final Assembly

- Team assignment

week09-Mechanical Design, Machine Design

Week 9 - Overview

In the ninth week of our course, we were tasked with completing the assembly of a large machine.

I was assigned the responsibility of assembling and debugging the machine.

Thanks to my team members and their trust in my mechanical design skills, I was able to complete this assignment swiftly.

- design a machine that includes mechanism+actuation+automation+application - build the mechanical parts and operate it manually - document the group project and your individual contribution

Reference Links

week09-Mechanical Design, Machine Design Guide for my Fab Academy Journey.Introduction and Project Task Distribution

Introduction

Blot: The Plotting Robot

This week, we are focusing on a plotting robot named Blot, which is being presented by Leo and his teammates from Hack Club.

The development of Blot was supported by MIT’s Center for Bits and Atoms, illustrating a collaboration that harnesses both community-driven innovation and academic resources.

Blot Github Repository

Blot: CNC Drawing Machine

Blot is a custom CNC drawing machine designed to perform artistic creations such as writing and painting.

The functionality of Blot is driven by software developed in the Arduino IDE, which controls a servo.

This servo manipulates the movement of the robotic arm via a timing belt, allowing for precise and creative artistic outputs.

Project Task Distribution

Introduction and Project Task Distributio>

| Task | Assigned To |

|---|---|

| Mechanical Design and Fabrication | Chenxin |

| Electrical Design and Fabrication | Crail & Jiawei |

| Software Design and Debugging | Crail & Matthew Yu |

| System Integration and Debugging | Matthew Yu & Dion |

| Production of Promotional Materials, Videos, etc. | Dion & Katherine |

My contribution in this group project is as follows:

first, I addressed the issue of needing to procure new parts due to misfit components throughout the project.

Secondly, during the assembly process, I ensured that it met the reliability standards required for a machine.

Furthermore, I completed the assembly testing of the mechanical parts.

This summarizes my contributions to the group project.

Work Process

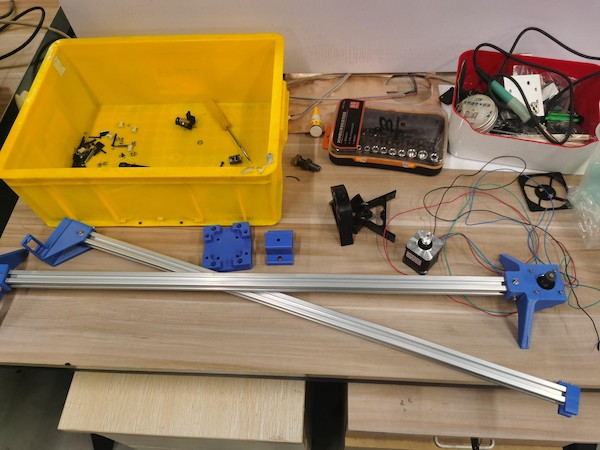

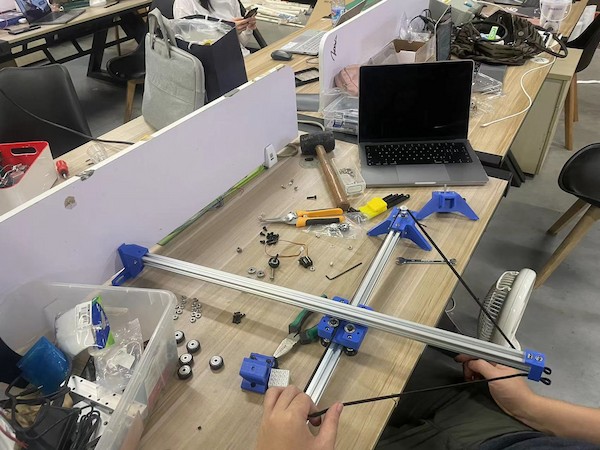

Part Inspection and Basic Assembly:

Upon receiving the mechanical parts, I noticed several were missing. I started with assembling the parts that were available.

Purchasing Guide Wheels:

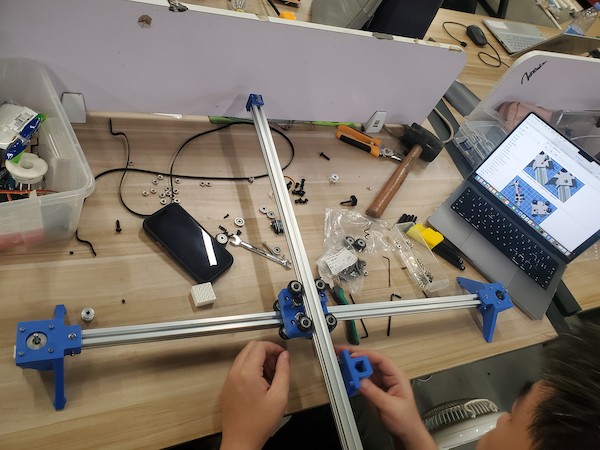

During the assembly, I realized we were short on wheels, so a few of us rushed to the hardware store at midnight to purchase guide wheels. Ultimately, we could only find some of the necessary parts, and had to order the rest online.

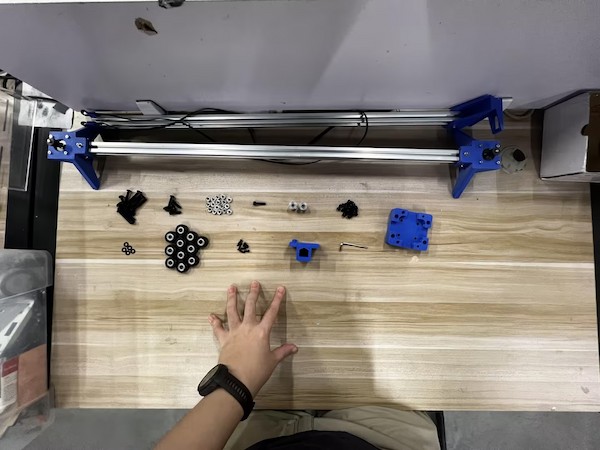

<Part Layout and Checklist Verification:

The ordered parts arrived on schedule, and I arranged them on the table to check against the BOM, ensuring all parts were accounted for.

Using Chaihuo Maker Space Parts:

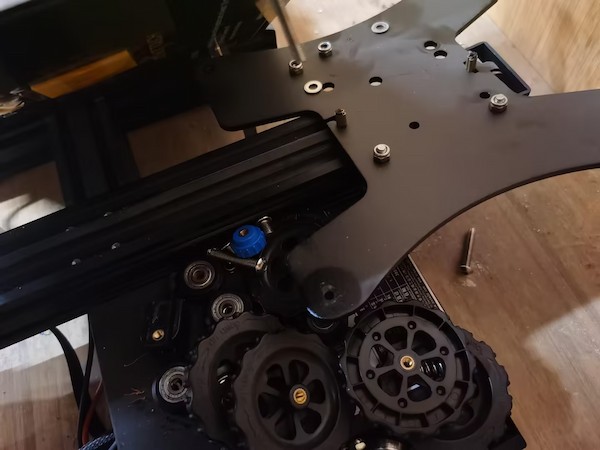

We were missing some parts, so we located an Inder printer in the Chaihuo Maker Space, which was built with OpenBuild components. We dismantled it to use many of its parts for our own machine.

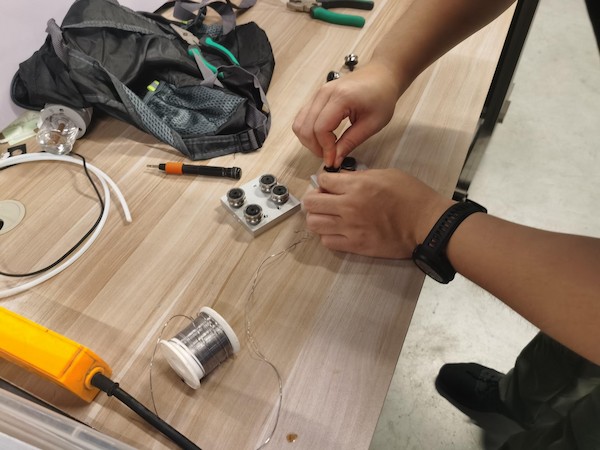

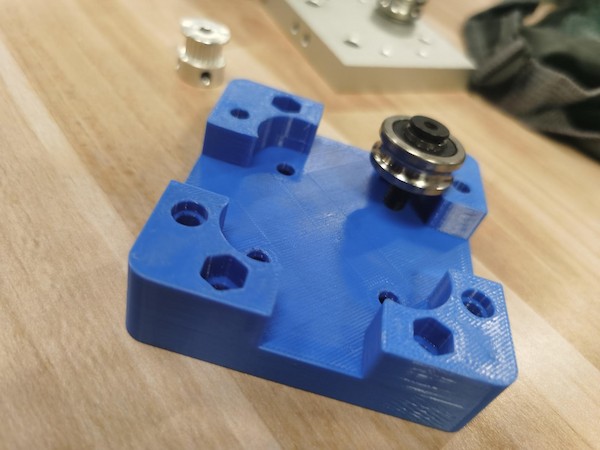

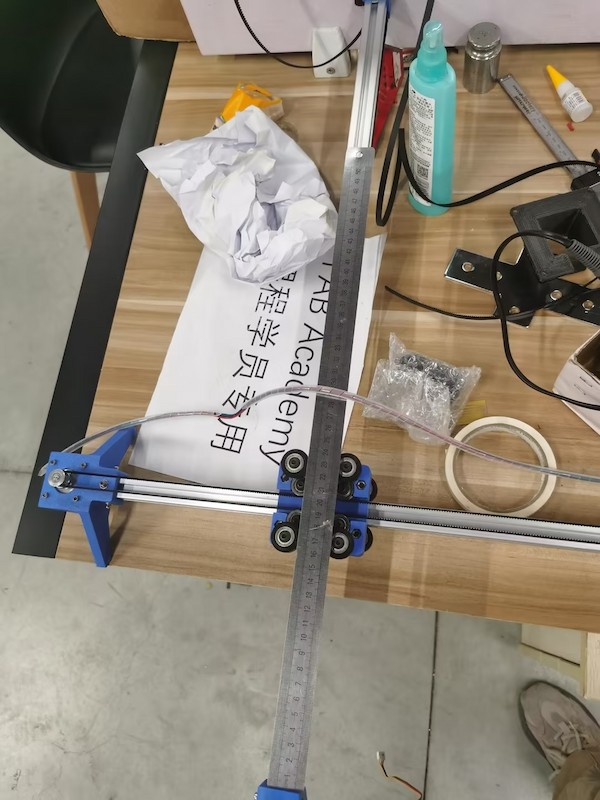

Part Fitting and Adjustment:

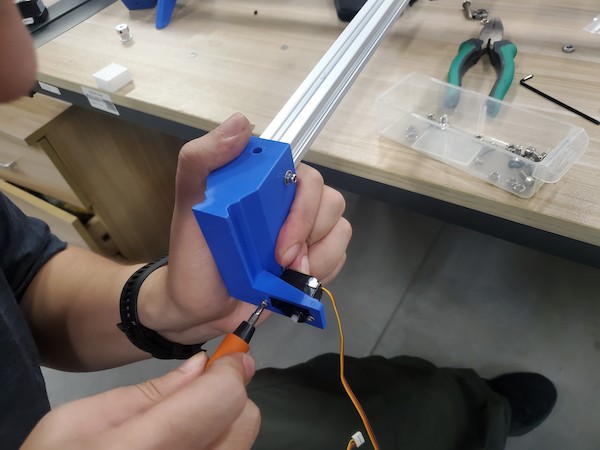

After acquiring these parts, I noticed some dimensional discrepancies but managed to improve assembly precision using electric coils. During the installation of the eccentric wheel nuts, due to the lack of metal support in the base, I installed and adjusted the eccentric wheel nuts as gently as possible.

Flexibility Testing and Troubleshooting:

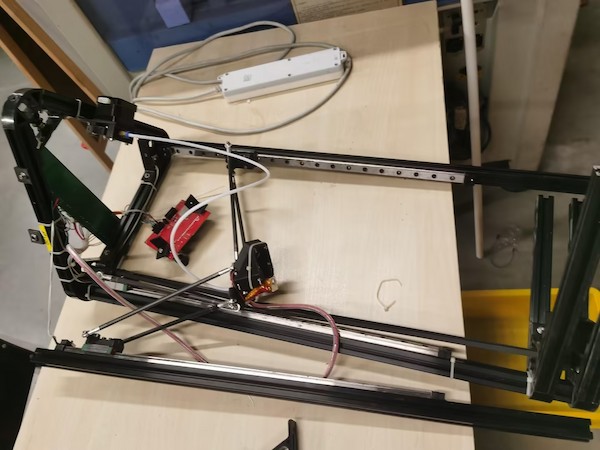

After assembly, I conducted a flexibility test. I encountered an issue with the servo interface. My classmate, Matthew Yu, mentioned some minor issues he faced during installation. After inspecting, I managed to fix the servo component’s positioning, successfully assembling the machine’s framework.

Belt Purchase and Final Assembly:

Another problem arose with the belt's length being too short. My classmate Katherine drove over ten kilometers away to buy the correct belt and delivered it on time. With the belt, I completed the final assembly of the machinery.

Team Assignment

I completed this segment of the project on schedule.

This assembly process not only allowed me to fulfill the task but also provided me with new knowledge about the equipment.

Thanks to everyone for their trust.

Group Assignment link.

Let's Jump to the Top !!!